With the rapid development of the 3C digital industry, the 3C digital products are being upgraded towards the direction of high integration and high precision. The internal components of the products are getting smaller and smaller, and the precision and electronic integration are getting higher and higher. Therefore, the internal structure of the appearance, deformation, drawing force to mark, welding technology

And it gets higher and higher. Because of its high energy, high precision and high directivity, laser products are widely used in the internal structure of 3C products. In the current production process of high-end digital equipment, laser technology plays an important role in product volume optimization and quality improvement

Product more light and thin, stable and so on.

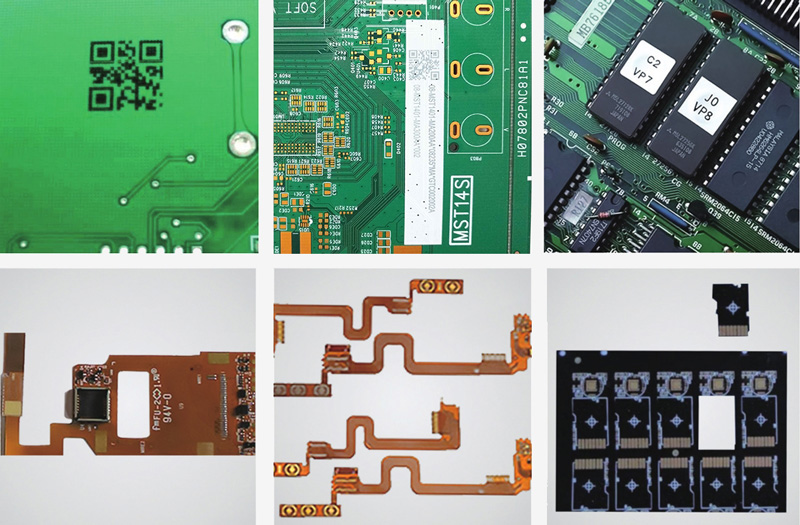

PCB is one of the important components in the electronics industry, and the industrial output value accounts for about a quarter of the total output value of electronic components. It occupies the largest proportion in each electronic component subdivision industry. With the increasing demand for smart phones and other wearable electronic consumer goods, the rapid development of the PCB industry has been further promoted

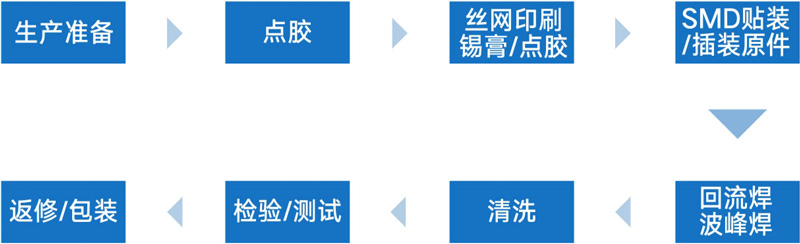

Speed of development. The emergence of laser technology in the industry has led to explosive growth of PCB industry. The application of laser technology in PCB industry mainly includes four aspects: laser cutting, laser welding, laser measurement and laser marking.

1. The laser processing method is non-contact processing, and the thermal influence area of components is small during the processing.

Second, the laser processing molding more fine, to achieve micron processing, in the electronic circuit board micro hole production and shaped its advantages are particularly prominent.

3. High accuracy of laser processing, laser beam spot diameter up to 1 m, can be ultra-fine processing. It is non - contact processing, no obvious mechanical force, easy to locate and identify and ensure high machining accuracy.

The laser processing material range is wide, suitable for processing all kinds of metal and non-metal materials.

Good laser processing performance, no special requirements for the processing site and working environment, no vacuum environment, no radioactive radiation, no pollution. Laser processing speed, high efficiency, flexible and simple.

18667815196

18667815196